- Nuclear Reactors, Boilers, Machinery And Mechanical Appliances; Parts Thereof

- Machines For Cleaning, Sorting Or Grading Seed, Grain Or Dried Leguminous Vegetables; Machinery Used In The Milling Industry Or For The Working Of Cereals Or Dried Leguminous Vegetables, Other Than Farm-type Machinery.

- Machinery Used In The Milling Industry Or For The Working Of Cereals Or Dried Leguminous Vegetables (excl. Farm-type Machinery, Heat Treatment Equipment, Centrifugal Dryers, Air Filters And Machines For Cleaning, Sorting Or Grading Seed, Grain Or Dried Leguminous Vegetables)

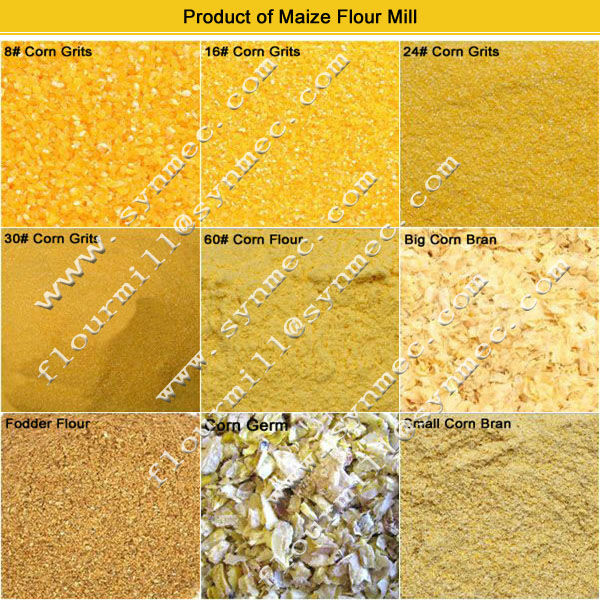

20T/D 6FYDT Maize Milling Machines

Product Images

Product Property

| Product Status : | New |

| Sample Available : | no |

| Shipment Terms : | fob |

| Payment Mode : |

T/T,L/C,D/P,D/A,WesternUnion,MoneyGram |

Description

20T/D 6FYDT Maize Milling Machines

--- All our flour milling plant are provided with Oversea Installation and Trainning

Introduction

Professionally supply the 20T/D maize milling machines to produce different grades flour and grits through special technical design for customers needs.

Structure

This kind of flour milling plant has two parts, cleaning part consists of sieving, debating, destoning, dampening machines and the milling parts mainly adopts 6F2240 roller mill or 6F1820 Roller Mill, and round sieves or double bin sifters.

Features

1. Roller mills are manufactured precisely and controlled by pneumatic mode. It can make better grinding effect comparing with other ordinary mills.

2. Complete sets of wheat flour processing machine adopt various configuration modes for different choices. There are streamlined design, reasonable layout, beautiful performance . It can be installed on a steel frame

structure or in a building structure.

3. The flour processing machine is with advanced technical process and flexible adjustment. It can produce grade flour and special flour etc.

4. Perfect after-sales service is also supplied for complete set of flour processing machine.

Parameter

| Model | 6FYDT-20 |

| Production Capacity (T/24h) | 18~28 |

| Main machines andprocessing techniques | High efficiency vibration sifter, Destoner, Peeling Crusher, Polisher, Roller mill, Grading Machine, single-section plansifter, Whole dry-method processing |

| Products and extraction rate (%) | Corn flour: 40-50% Corn grits: 35-40% Corn bran, coarse fodder:10-12% Embryo: 8-10% It can produce fine corn flour (all through 100M fiter) |

| Products quality index | Sand content: ≤0.02% Fat content: ≤2.5% Magnetic metal content: ≤0.003% Moisture content: ≤13.5-14.5% (based on the raw corn according with national standard for raw grain storage) |

| Power required (kW) | 86 |

| Size of workshop(L×W×H, m) | 20×7×5 |