- Rubber And Articles Thereof

- Tubes, Pipes And Hoses, Of Vulcanised Rubber Other Than Hard Rubber, With Or Without Their Fittings (for Example, Joints, Elbows, Flanges).

- Tubes, Pipes And Hoses, Of Vulcanised Rubber (excl. Hard Rubber), Not Reinforced Or Otherwise Combined With Other Materials, Without Fittings

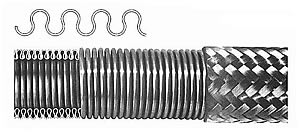

Metal Hose

Product Images

Product Property

| Product Status : | New |

| Sample Available : | yes |

| Shipment Terms : | fob |

| Payment Mode : |

Negotiable |

Description

Metal Hose Protects Cable Wire, Gas, Liquid Transport

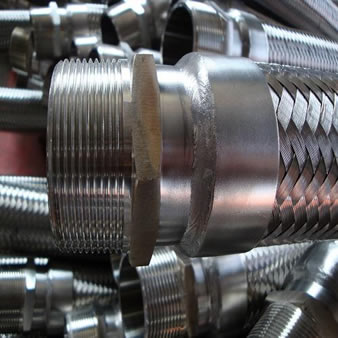

Metal hose with screw thread to make it install easily

Metal hose also named flexible metal conduit is a high quality flexible pipe in modern industrial pipeline and it is more strong than flexible corrugated nylon conduits. It consists of corrugated hose, nets and connector. The inner corrugated hose made of stainless steel has helical and annular shapes. The nets are made of steel wire braided. It plays the reinforcement function. The connectors consist of screw thread, flange and quick coupling. All the connectors make it install easily and connected strongly. It is used as the compensation components, sealing elements, connecting elements and damping elements for gas, liquid transportation system and high temperature system.

Specification:

- Braided mesh material: SS304.

- Braided mesh layer: single layer or double layers.

- Inner pipe material: 304, 321 and 316L stainless steel.

- Inner pipe type: annular corrugated, helical corrugated.

- Pipe thickness: 0.28-1.5mm.

- Size range: DN8mm to DN400mm.

- Max. working pressure: 10MPa.

- Working temperature: -200°C - +600°C.

- Connect material: stainless steel or carbon steel.

- Connect type: flange, thread, quick coupling.

- Flange standard: ANSI, JIS, DIN, GOST, etc.

- Thread Standard: NPT/BSP.

- Hose standard: GB/T14525-93.

| Model | Hose I.D | Hose O.D | Minimum Bend Radius | Working Pressure (MPa) | |||

| Main Body | Single Braid | ||||||

| Inch | mm | mm | mm | mm | Single Braid | Double Braid | |

| HMH-6 | 1/4 | 6.3 | 9.0 | 10.5 | 150 | 6.4 | 10.0 |

| HMH-7 | 5/16 | 7.9 | 10.9 | 12.5 | 160 | 6.4 | 10.0 |

| HMH-10 | 3/8 | 10.8 | 15.2 | 16.8 | 180 | 5.0 | 8.0 |

| HMH-13 | 1/2 | 13.4 | 18.5 | 20.0 | 240 | 4.0 | 6.4 |

| HMH-16 | 5/8 | 16.0 | 21.5 | 23.0 | 300 | 3.5 | 5.0 |

| HMH-19 | 3/4 | 19.1 | 25.6 | 27.2 | 340 | 3.0 | 4.5 |

| HMH-25 | 1 | 25.4 | 32.6 | 34.2 | 400 | 2.5 | 4.0 |

| HMH-32 | 1-1/4 | 32.9 | 40.6 | 42.2 | 480 | 2.5 | 4.0 |

| HMH-39 | 1-1/2 | 39.3 | 47.6 | 50.2 | 600 | 2.5 | 4.0 |

| HMH-50 | 2 | 50.8 | 61.5 | 63.5 | 780 | 2.5 | 4.0 |

| Model | Hose I.D | Hose O.D | Minimum Bend Radius | Working Pressure (MPa) | |||

| Main Body | Single Braid | ||||||

| Inch | mm | mm | mm | mm | Single Braid | Double Braid | |

| AMH-14 | 1/2 | 14 | 20 | 22 | 120 | 7.5 | 12.5 |

| AMH-16 | 5/8 | 16 | 23 | 25 | 150 | 6.4 | 10.0 |

| AMH-20 | 3/4 | 20 | 28 | 35 | 180 | 5.0 | 8.0 |

| AMH-25 | 1 | 25 | 35 | 37 | 280 | 4.0 | 7.5 |

| AMH-32 | 1-1/4 | 32 | 43 | 45 | 340 | 3.5 | 6.4 |

| AMH-40 | 1-1/2 | 40 | 51 | 53 | 450 | 3.0 | 5.6 |

| AMH-50 | 2 | 50 | 62 | 64 | 550 | 2.5 | 4.0 |

| AMH-65 | 2-1/2 | 65 | 79 | 82 | 650 | 2.0 | 4.0 |

| AMH-80 | 3 | 80 | 97 | 100 | 800 | 2.0 | 3.2 |

| AMH-100 | 4 | 100 | 122 | 125 | 1000 | 1.6 | 2.5 |

| AMH-125 | 5 | 125 | 151 | 155 | 1200 | 1.5 | 2.5 |

| AMH-150 | 6 | 150 | 180 | 184 | 1500 | 1.5 | 2.5 |

| AMH-175 | 7 | 175 | 210 | 215 | 1750 | 1.2 | 2.0 |

| AMH-200 | 8 | 200 | 240 | 245 | 2000 | 1.2 | 2.0 |

| AMH-250 | 10 | 250 | 298 | 303 | 2200 | 1.0 | 1.6 |

| AMH-300 | 12 | 300 | 360 | 365 | 2500 | 1.0 | 1.6 |

| AMH-350 | 14 | 350 | 410 | 415 | 3000 | 0.8 | 1.2 |

| AMH-400 | 16 | 400 | 460 | 465 | 3500 | 0.6 | 1.0 |

Feature:

- Fatigue resistance.

- Corrosion resistance.

- High flexibility.

- High and low temperature resistance.

- High pressure resistance.

- High physical strength.

- High flexible pitches of metal hose.

- Good scalability, no-blocking and stiffness.

- Light weight and good caliber consistency.

- Good flexibility, repeated bending resistance.

- Moisture resistant.

- Resist abrasion, penetration and damage

Parallel structure core metal hose

Duo structure core metal hose

Single layer braided steel wire protects hose from damaging

Double layer braided steel wire metal hose enhances the anti-pressure resistance

Metal hose screw thread makes securely connected

Metal hoses carton box packing makes it transport easily

Application:

Metal hose is widely used to transport air, smoke, liquid gas, all kinds of industrial gas. Also used for steam transfer, water, oil, food process, chemical and high temperature installations.